Traditional manual inspection techniques often struggle to keep up with the vast amount of data generated in large-scale manufacturing. This leads to increased production downtime, safety hazards, and quality control issues, significantly impacting operational efficiency. Computer vision provides a powerful solution to address these challenges, offering a scalable approach to automation in manufacturing industries. Studies predict that vision AI could boost production by nearly 40%.

In this article, we will explore how computer vision is revolutionizing the manufacturing sector, its role in defect detection, and how businesses can establish a scalable AI-driven computer vision platform. We will also discuss the key challenges and future potential of this transformative technology.

Understanding a Scalable Computer Vision System

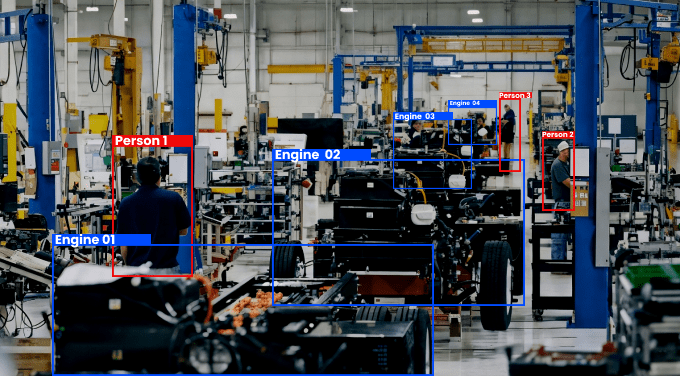

Computer vision, a subset of artificial intelligence (AI), enables machines to analyze images, identify objects, and interpret events in real-time. However, scalability is crucial for achieving widespread adoption across industries. A scalable computer vision system requires advanced computing infrastructure capable of processing vast amounts of visual data efficiently. AI-driven platforms allow enterprises to deploy and manage computer vision applications seamlessly, ensuring optimal performance across manufacturing operations.

Leveraging the Power of Computer Vision in Manufacturing

Computer vision technology enhances efficiency by enabling machines to process image and video data with higher speed and accuracy. Several applications of computer vision in manufacturing have significantly transformed manufacturing operations, including:

Predictive Maintenance

Equipment maintenance is critical for ensuring seamless manufacturing operations. Conventional maintenance approaches are often time-consuming and costly. AI-driven computer vision systems analyze video footage in real-time, identifying potential issues before they lead to downtime. According to McKinsey, predictive maintenance enabled by AI can reduce maintenance costs by up to 40% and minimize downtime by 50%.

Quality Control

AI-powered computer vision is instrumental in improving quality control processes. Traditional manual inspection methods are prone to human error, but vision AI can accurately detect defects in real-time. By analyzing images captured from production lines, AI systems identify faulty products, allowing manufacturers to make immediate adjustments. This automated quality control process enhances product reliability while reducing waste.

Process Optimization

Manufacturers can leverage computer vision technology to optimize production processes. AI-powered cameras analyze workflow sequences, detecting inefficiencies and potential bottlenecks. By providing real-time insights, vision AI helps manufacturers refine processes, enhance productivity, and minimize operational costs. This technology ensures continuous process improvement, leading to higher overall efficiency.

Real-time Safety Monitoring

Safety compliance is a top priority in manufacturing facilities. AI-driven computer vision systems can detect unsafe worker behavior, PPE violations, and hazardous conditions in real-time. These systems proactively alert safety personnel, reducing the risk of workplace accidents. Object detection algorithms enable automated monitoring of restricted areas, ensuring that workers adhere to safety regulations.

Challenges in Scaling Computer Vision in Factories

While computer vision presents a promising solution for manufacturing, scaling AI-powered systems poses certain challenges:

Computational Resources

Advanced AI models require significant computational power for real-time data processing. Deploying these systems at the edge, rather than relying solely on cloud computing, can alleviate some of this burden. However, edge computing comes with its own set of deployment challenges, including hardware limitations and network constraints.

Model Training

Developing and training AI models for computer vision requires large datasets. Labeling and curating this data is both time-consuming and expensive. Moreover, maintaining model accuracy over time requires continuous training and updates. Effective model management strategies are essential for ensuring consistent performance across different manufacturing environments.

Integration with Existing Systems

Manufacturing plants operate with complex legacy systems, making integration a significant challenge. Computer vision solutions must be seamlessly incorporated into existing infrastructure while ensuring interoperability between various production systems. Addressing data exchange and compatibility issues is crucial for successful deployment.

Core Elements of Scalable Computer Vision Technology

To build a scalable and efficient computer vision platform, manufacturers must focus on the following core elements:

- Monitoring & Management Tools: Real-time monitoring systems ensure smooth operation and identify potential bottlenecks in the production line.

- Advanced Algorithms & Models: AI-powered models improve accuracy in defect detection, process optimization, and safety monitoring.

- Modular & Microservices Architecture: A flexible architecture enables easy updates and seamless integration with existing systems.

- Data Acquisition & Management: Effective data collection and processing enhance the performance of vision AI applications.

- Edge Computing: Reducing dependency on cloud infrastructure by processing data closer to the source improves efficiency.

- Cloud Infrastructure: Cloud-based solutions provide scalability, allowing manufacturers to manage AI applications across multiple locations.

The Future of Scalable Computer Vision Systems

In the coming years, computer vision platforms will continue to evolve, integrating with advanced AI models, edge computing, and real-time analytics. These advancements will enable manufacturers to enhance automation, reduce operational risks, and improve production efficiency. AI-driven analytics tools will allow businesses to refine their processes based on real-time insights, ensuring they stay ahead of industry demands.

A scalable computer vision platform represents a strategic investment for large-scale manufacturing operations. By going beyond traditional techniques, manufacturers can significantly improve product quality, operational security, and overall efficiency.

Final Thoughts

Computer vision technology powered by AI is reshaping the manufacturing sector by enabling real-time surveillance, defect detection, and automated process optimization. To fully leverage its potential, manufacturers must invest in scalable AI solutions that can adapt to evolving industry requirements.

Nextbrain offers cutting-edge AI Video Analytics software designed to automate manufacturing operations and provide real-time monitoring. Our solutions empower businesses to streamline processes, enhance quality control, and ensure workplace safety.

Are you ready to implement a scalable computer vision solution in your manufacturing facility? Connect with our experts to learn more about vision AI and how it can transform your business operations.