In early manufacturing processes, traditional quality control heavily relied on manual inspection, leading to inefficiencies and inconsistencies. Over time, industries have adopted mass defect detection technologies to streamline their quality control operations. Despite advancements, ensuring high-quality production remains a persistent challenge.

Computer vision has emerged as a revolutionary solution in various sectors, including automotive, healthcare, retail, and manufacturing. This technology is capable of analyzing vast databases, recognizing images, and identifying anomalies, significantly improving defect detection and operational efficiency. In this article, we will explore how computer vision is enhancing quality control and defect detection across different industries.

What is Computer Vision?

Computer vision is an advanced AI-driven technology that enables computers to process and interpret visual data from images and videos. It plays a crucial role in quality control by helping businesses extract essential insights for detecting flaws and anomalies in production. With AI-powered recommendations, computer vision aids human decision-making, ensuring higher accuracy and productivity in manufacturing and other industries.

Leveraging Computer Vision for Flaw Detection

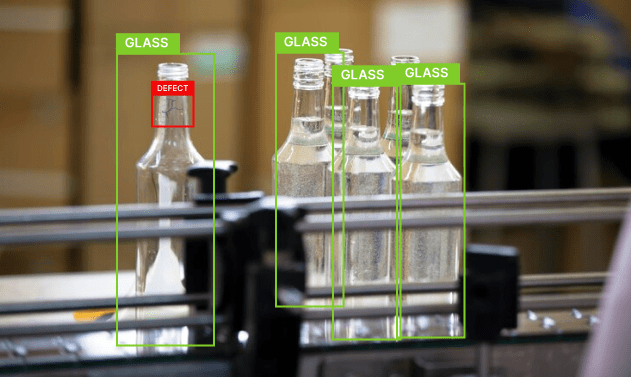

Computer vision models are trained to recognize patterns and features that distinguish defective products from non-defective ones. By utilizing vast datasets, these models can detect faults in real-time, enhancing the speed and accuracy of quality inspections. Businesses can also develop custom models tailored to their specific requirements, optimizing defect detection across production lines.

The Importance of Visual AI Defect Detection in Manufacturing

Defective Product Detection

Computer vision in defect detection analyzes product orientation, texture, and positioning, identifying anomalies with high precision. Manufacturing companies that integrate computer vision into their quality control processes benefit from improved accuracy, reduced errors, and faster defect identification. This ensures the production of high-quality products, leading to increased customer satisfaction.

Reduces Labor and Operational Costs

Manual inspection is time-consuming, error-prone, and poses safety risks to workers. Computer vision automates the inspection process, reducing labor-intensive operations and minimizing human error. By implementing AI-driven defect detection, businesses can enhance efficiency while cutting down operational costs. Vision AI-powered image processing tools facilitate rapid and precise inspection across production lines, enabling businesses to maintain high productivity levels.

Optimizes Material Inspection

Material inspection plays a crucial role in preventing manufacturing defects. Identifying poor-quality materials before production begins helps reduce waste, conserve resources, and minimize financial losses. Computer vision systems assist manufacturers in segregating defective raw materials early in the process, ensuring only high-quality inputs are used in production. This not only enhances final product quality but also improves overall operational efficiency.

Predictive Maintenance with Computer Vision

Predictive maintenance with computer vision Defect detection automation powered by computer vision plays a vital role in predictive maintenance. AI-driven predictive analytics can forecast equipment failures and maintenance needs, allowing businesses to address issues proactively. By predicting potential malfunctions, companies can reduce downtime, enhance product quality, and optimize operational costs. Computer vision AI in manufacturing enables businesses to implement real-time monitoring and predictive maintenance strategies, ensuring seamless production workflows.

Ensuring Worker Safety and Security

Maintaining workplace safety is essential in manufacturing environments. Computer vision enables real-time monitoring of production units, ensuring compliance with safety regulations. AI-powered vision systems can detect whether employees are wearing personal protective equipment (PPE) such as masks and helmets. If a safety violation occurs, facility managers receive instant alerts, allowing them to take corrective actions and maintain a secure working environment.

Recognizing Defects in Packaging

Ensuring product quality extends beyond manufacturing to packaging. Packaging defects can lead to damaged goods, customer dissatisfaction, and financial losses. Vision AI identifies packaging flaws by analyzing distinct image attributes, detecting damages, and ensuring high packaging standards. Deep learning and neural networks enable vision AI to verify product integrity before items reach consumers, reducing errors and improving production efficiency.

Barcode Generation and Analysis

Accurate barcode verification is critical for product tracking and inventory management. Computer vision systems efficiently scan and validate barcodes, detecting any inconsistencies or defects. If a faulty barcode is identified, it is flagged for removal or correction, ensuring accurate product information and seamless inventory operations.

Enhancing Inventory Management

Vision AI supports inventory management by tracking stock levels and monitoring warehouse operations. Businesses benefit from automated stock monitoring, which ensures accurate inventory tracking and timely replenishment. Computer vision provides facility managers with real-time updates, making inventory control more efficient and reliable.

Workplace Safety for Workers

Ensuring workplace safety is a top priority for businesses. Vision AI helps maintain a secure environment by monitoring safety compliance. AI-powered surveillance systems can detect whether employees are adhering to safety protocols, such as wearing PPE. Facility managers receive real-time alerts when violations occur, allowing them to address safety concerns promptly. This proactive approach reduces workplace accidents and enhances overall security.

Leveraging Object Detection for Flaw Identification

Computer vision automates flaw detection using pre-trained object detection models. AI-based platforms like Roboflow Universe provide access to open-source datasets and pre-trained models, simplifying the deployment of vision AI applications. With tools like Roboflow inference, businesses can seamlessly integrate defect detection models into their production systems. By implementing AI-driven object detection, companies can achieve higher accuracy and consistency in flaw identification.

Beyond Manufacturing: Vision AI in Electronics

Computer vision is not limited to manufacturing but extends to electronics defect detection. It accurately identifies defects such as scratches, cracks, and missing components, preventing faulty products from reaching the market. AI-powered vision systems minimize financial losses by detecting flaws early, ensuring only high-quality electronics are distributed. These automated systems provide faster, more reliable, and consistent defect detection compared to traditional methods.

Final Thoughts

Computer vision has transformed quality control by automating defect detection and eliminating faulty products before they reach consumers. Traditional manual inspection methods have been replaced by AI-driven vision systems, improving efficiency and reducing errors. Object detection models help businesses fine-tune specific quality control processes, ensuring seamless integration with automated assembly lines.

At Nextbrain, our team of AI experts specializes in defect detection solutions tailored to various industries. We offer comprehensive AI Video analytics software designed to enhance quality control and operational efficiency across different sectors.

To learn more about how computer vision AI can revolutionize your business, connect with our professionals today.