Forklifts are critical vehicles for moving heavy goods, optimizing available storage space, and helping to maintain smooth operations in facility environments when moving freight such as warehouses, logistics centers, factories, and retail storage areas.

Unfortunately, as beneficial as forklifts are, they happen to make up one of the largest contributing factors to workplace accidents. A certain number of accidents occur from property damage and serious injury each year in facilities with forklifts. As there is a large focus on productivity and ever-evolving complexity surrounding safety in industrial environments, facilities are working to implement technology solutions to manage hazards without reliance on human beings.

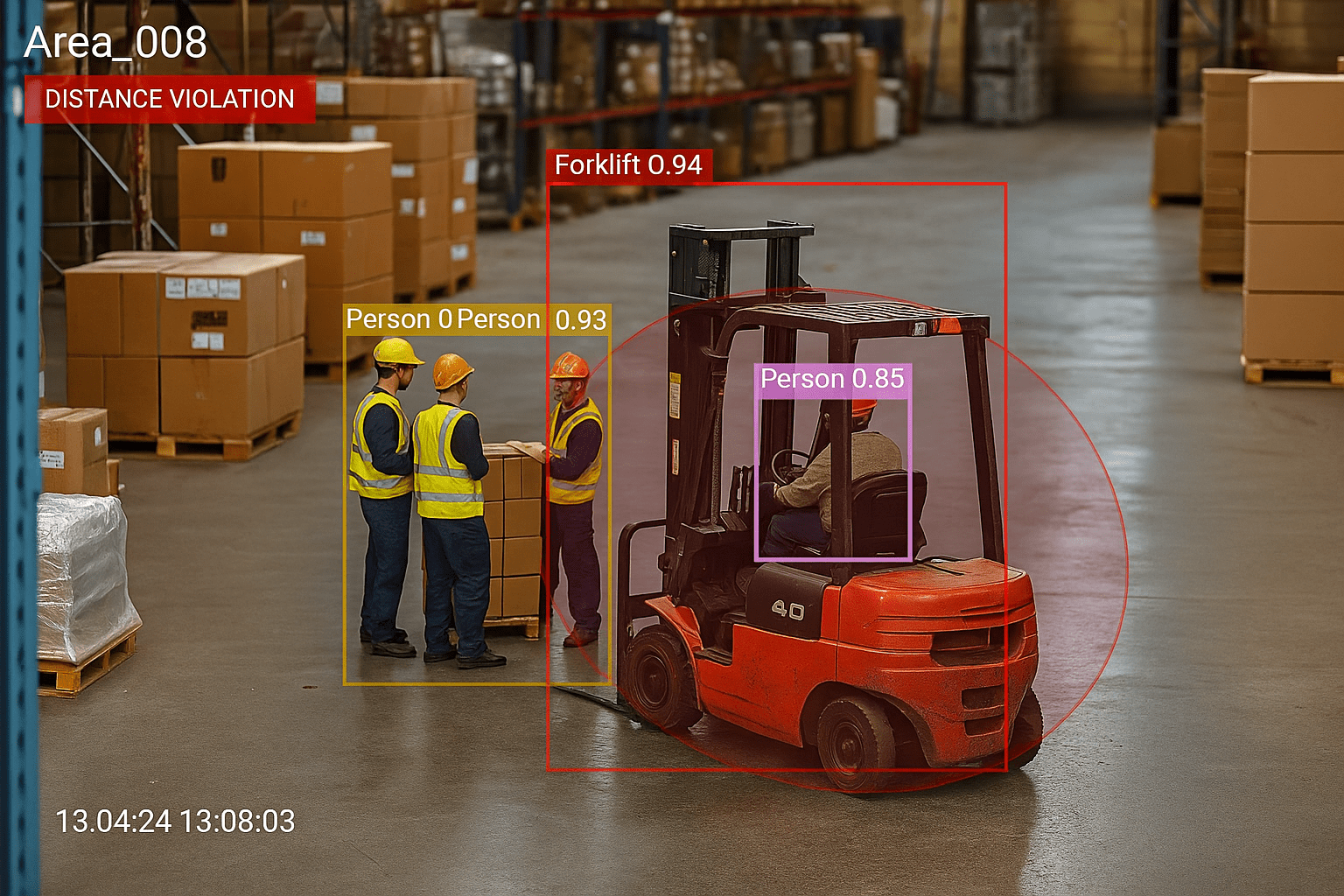

One of the most relevant advancements in this area is an AI-enabled Forklift Collision Avoidance System with Computer Vision for Forklift Safety. The advent of visual intelligence with real-time analytics has put us in a new realm of safety in industrial facilities, empowering facilities to identify and respond to hazards with incredible precision.

The Unconquerable Problem of Pedestrian Safety in the Presence of Forklifts

While forklifts can sometimes seem small, they can weigh over 10,000 lbs, which means they can leave pedestrians with terrible injuries like fractures, strains or damaged muscles. Of course, we have used administrative controls like restriction on operating forklifts in certain areas for pedestrians with earmaps, and signage, and have made some improvements, but accidents still happen.

Some high-risk scenarios include the following:

- Narrow aisles that bring the pedestrian and the forklift close to each, without much further distance to maneuver.

- Blind corners where the operator cannot see the pedestrian in the approach.

- Limited visibility when the forklift is in reverse.

- Distracted employees who do not seem to be aware of the fork trucks operating in their area of movement.

These hazards have always existed – but, there is a new layer of safety that can help – and that is computer vision with AI that is able to monitor surroundings and areas for risks before they get out of hand.

The Importance of Computer Vision for Preventing Forklift Collisions Preventation

When pedestrians and forklifts share the same environment, safety should always come first. Traditional technologies that combat collisions often only rely on distance sensors, and in most practical situations, have a poor understanding of the complexity of the real world.

Computer vision changes everything. The system uses video cameras to visually comprehend the forklift’s surroundings through AI algorithms. The cameras can identify and categorize:

- Humans

- Other vehicles or forklifts

- Racks and pallets

- Obstacles or debris

Trained AI models specific to industrial environments can notify when unsafe actions or unsafe conditions are detected. This allows sites the opportunity to prevent incidents through action instead of reaction.

Enhancing Collision Avoidance with AI Vision

Nextbrain’s AI-powered Forklift Accident Prevention System is a state-of-the-art product designed to assist EHS (Environment, Health, and Safety) departments in enhancing workplace safety standards. Utilizing real-time data processing, computer vision, and automated alerts minimizes accident hazards.

- Real-time alerts when a restricted zone is violated

Suppose a pedestrian or other vehicle enter the restricted forklift zone. In that case, the system can send real-time alerts to supervisors and forklift operators which gives the ability to implement immediate action and minimizes accidents. - Recognizing Unsafe Proximity

With AI-powered computer vision, the system examines the distance between forklifts, pedestrians, or other vehicles on a continuous basis. If unsafe proximity is identified, an alarm is initiated and notifications are sent out for follow up and corrective action to be implemented. - Recognizing Recurrent Issues

Some safety risks are actually a factor of some type of recurring unsafe event, working or task inefficiencies or unsafe behaviors inappropriately repeated while continuing to be overlooked. These unsafe events could be recognized in the data by the AI system via heatmapping capability in comparison with the larger data set analysis to allow managers to intervene at the root. - Understanding Movement Patterns Using Heat Maps

Vision AI enhanced heat maps can provide information regarding patterning of walking pedestrians and operating forklifts, identifying higher risk zones, and allowing better layout planning (physical environments) to minimize probable even of collision. - Data Building for Continual Improvement

Over time, this system will accumulate substantial amount of pedagogy of interactions between forklifts and operators when both are in operation. This knowledge will serve a particularly useful purpose, validating infrastructure current safety measures and informing continual improvements.

Reasons Industries are Implementing Vision AI-Based Collision Avoidance Systems

Traditional sensor-based forklift safety systems often fall short in identifying complicated and dynamic hazards. Vision AI is designed to overcomes these disadvantages. Vision AI combines real-time image recognition with analytics to provide value that goes beyond identifying basic obstacles.

Key Value Propositions:

- Minimized damages to freight through reducing incidences of unintended collisions.

- Reduced downtime through early alerting of hazards.

- Increased level of compliance with workplace safety regulations.

Vision AI Advantages for Forklift Safety

Higher standards of workplace safety

Using Computer vision for Forklift Safety , facilities can enforce higher standards of safety guidelines and protocols, protecting their own staff and, allowing an operator to concentrate on their job with confidence.

Greater Operational Awareness

Vision AI ultimately gives forklift operators a views of their surrounding environment, rather than relying on guess work. This improves decision making and reduces potential for human errors.

Fewer Collisions and Down time

Timely alerts allow to prevent an incident from becoming an incident. Less accidents with fewer incidents translates to a smoother work flow with reduced potential costly operational impacts.

The Future of Safety in Forklifts

Forklift safety is not just a high-visibility vest, mirrors, and operator diligence any longer. By utilizing AI-powered computer vision forklift collision avoidance systems, facilities have begun adopting data-infused, proactive safety infrastructure.

Traditional methods often created blind spots for safety – literally and figuratively. Modern vision AI removes these gaps, driving the workplace to be both human aware and machine aware which leads to a more efficient and safer overall operating environment.

Final Thoughts on Workplace Safety

Workplace safety and health is more than just rules, it is developing an atmosphere where hazards are continuously monitored, anticipated and prevented. AI-driven Computer Vision for Forklift Safety is a giant step forward in that journey.

Our system can locate hazards in real-time, present visual patterns, and iterate on processes backed by data. This will give you unprecedented access and visibility into the future of industrial safety. Furthermore, with vision AI, safety systems will now be machine-aware as well as human-aware creating a new age of learning for accident prevention.

Are you ready to help improve your forklift safety and mitigate risk of accidents with computer vision? Contact us today and let us show you how this technology can change the safety of your operation while improving the overall efficiency of your business.

Frequently Asked Questions

- What is a forklift collision avoidance system with vision AI?

A safety solution that uses AI-powered cameras to detect people, obstacles, and vehicles in real-time. It then analyses the visual data to warn operators and prevent collisions, thereby improving overall workplace safety. - What hazards can computer vision detect?

Forklift-human interactions, humans in blind spots, interactions with other forklifts and vehicles, unsafe human behaviors such as speeding in tight zones, structural hazards, among others. - How does the AI-powered system prevent potential collisions?

The AI-powered system uses AI Video Analytics software to issue real-time alerts which are differentiated by visual indicators, data algorithms, and even audible alarms. In some cases, it can even automatically slow down the forklift to lessen the impact of a collision. - How does computer vision reduce accident risk with technology that uses AI?

It provides real-time situational awareness while issuing anticipated warnings to prevent collisions before they happen, thus minimizing lost time, injuries, and risk to safety. - What industries could use this technology?

Industries such as the automotive, manufacturing, food & beverage, construction, or retail industries can benefit from AI-enabled computer vision for forklift safety.