Solar power generated globally from solar power systems has quickly become one of the most sustainable sources of energy available on a global scale. With the increasing demand for renewable energy, maintaining large solar farms or dedicated facilities becomes more important. Traditionally, manual inspection was the only method of monitoring solar power systems. Now, manual inspection is becoming outdated, unreliable, time-consuming, complicated, and unsafe in some instances.

The inefficiencies and injustices associated with manual inspection are compounded when considering challenges such as microcracks, discoloration, dirt, extreme temperatures, and difficult access, making manual inspection of photovoltaic (PV) modules impractical and unpredictable. Due to these challenges, the solar space is now adopting computer vision AI for solar panel inspections demonstrating a substantial shift in inspection and maintenance systems.

Inefficiencies Associated with Manual Solar Panel Inspections

To understand AI’s role, you first need to understand the reason traditional methods are inadequate in today’s fast-moving solar environment.

Time Consuming

Manual inspections involve hours of checking and manipulating physical documents. In the case of large solar farms spanning hundreds of acres, inspecting and documenting panels is a slow and tedious process that significantly impacts efficiency overall.

Safety Risks

Inspectors often work in unsafe environments. Climbing onto rooftops and inspecting wires or modules under extreme conditions exposes inspectors to electrical shock or falling hazards.

Inconsistency of Data Accuracy

Manual inspections require human skill and experience. Variability in individual skill level (the motion of an inspector’s reach to inspect panels), the level of lighting, and the degree of human subjectivity with observations usually leads to a high degree of variability in data.

Labor-Intensive

Inspecting thousands of panels with highly skilled professionals is a costly endeavor. Visual checks and documenting data for thousands of modules is a resource-intensive process.

Inclement Weather / Accessibility Limitations

Rain, heat, or high degree of moisture may hamper inspections altogether. Additionally, some panels are located in hard-to-access, remote areas where inspecting panels may not be possible.

These limitations have made it apparent that solar farms must adopt a smarter, safer, and more scalable solution.

How Computer Vision AI is Changing Solar Energy

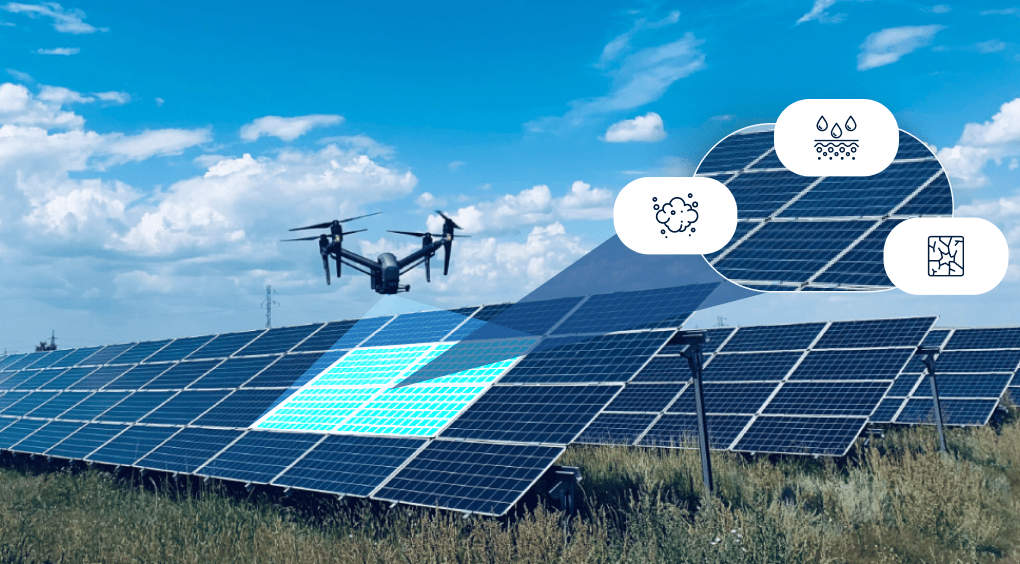

Enter Vision AI-powered drones. Unlike manual inspections, drones equipped with high-resolution cameras and AI Video analytics software capture detailed footage of solar panels, identify anomalies in real-time, and even predict potential failures.

These computer vision algorithms can analyze large datasets of solar panel imagery to find problems that are not visible to the naked eye and can classify problems into severity classes that defined levels of defects. By utilizing a deep learning structure, these AI systems can:

- Find cracks, debris on solar panels, and hotspots.

- Predict failures of the panel, doing trend analysis for the solar panel.

- Generate automated reports for the operators.

- Integrate into the maintenance system form restoring the panels in the repair and replacement.

This transition not only saves time and costs in the inspection of solar panels, but also contributes to the efficiency and longevity of solar panels.

Common Defects Found by AI-Powered Drones

Many times, solar panels develop defects due to wear and tear over time and in environmental conditions. Drones with Vision AI capabilities can automatically identify and remediate a range of common defects including:

Humidity & Moisture Damage

Finds defective panel surfaces related to weak seals and corrosion, along with electrical faults.

Dust & Pollution Build Up

Scans for thickness of dust on the surface of the solar panels that may affect the efficiency and power output of the installation.

Storm & Weather Damage

Drones can quickly identify damage related to storms, specifically overlaying cracks or debris damage after thunderstorms or adverse conditions.

Animal Damage

Drones can deter any scratches/bite externally or internally that birds or animals left on the panels.

Defective Bypass Diodes & Wiring

Identifies the faults of wiring and defective diodes and breakdowns that would provide defects or inefficiencies in power or electrical failure.

The Vision AI drones can provide real-time insights into drones and by documenting a findings, will effectively reduce time out of service to maximize energy efficiency.

How AI Drone Inspections Work

The process of a drone inspection powered by computer vision allows for precision, efficiency and accuracy in inspections:

Image & Video Acquisition

Drones with high-level cameras will scan a solar farm and take images and videos of the panels’ surfaces.

Data Retrieval

The visual data from the images and videos will be analyzed via computer vision, detecting dirt, dirt falling under panels, cracks, or hotspots.

Defect Detection

Using edge detection, statistics, and image processing techniques AI models can identify defects as small as the smallest doable defects.

Classification & Investigation

By deploying deep learning follow-on models the inspection will classify each defect by severity, or identifying normal condition from able to have problems.

Predictive Maintenance

The constant monitoring of a solar farm allows for a system to predict or enable a failure of equipment, and outline maintenance work doing predictive work to extend panels services years.

Automated Reporting

Reports, that often do the inspection too, have a level of detail that highlights the issues for prompt attention to those areas.

Integrated Maintenance System

The inspection will integrate with solar farm management system and automate scheduling repair or replacement appointments.

Real-Time Insights For Better Decision-Making

The true value of Vision AI drones is the actionable insights they provide, not just detecting defects. Using drone technology, operators can:

- Make urgent repairs a priority.

- Arrange for predictive maintenance.

- Optimize overall energy production.

This data-driven approach to digital transformation is deploying new layers of complexity, allowing for better decision-making that enhances efficiency and profitability throughout the solar industry.

Why Vision AI Drones Are Changing the Game

There is no comparison between AI-enabled drone inspections and manual inspections as there are several clear improvements –

- Speed & Efficiency – Inspect hundreds of acres in minutes.

- Higher Accuracy – Detect anomalies that are invisible to human inspectors.

- Cost Savings – Reduce labor costs and avoid unnecessary replacements.

- Safety – Remove human inspectors from dangerous situations.

- Scalability – Small rooftop systems or massive solar gardens.

Drones have completely changed the way solar panel inspections are done, bringing together agility and intelligence.

The Future of Solar Panel Inspections

The infusion of computer vision AI into solar panel inspections signals the dawn of a new epoch for renewable energy infrastructure. The application of predictive analytics, IoT connectivity, and automation will only enhance this evolution.

Solar farms using AI inspections will not only improve energy efficiency but will also generate sustainable, viable, and reliable energy into the future.

Final Thoughts

Using computer vision-powered drones to inspect solar equipment represents a monumental shift towards smarter, safer, and more sustainable energy management. By combining the accuracy of AI with the mobility of drones, solar producers may achieve unparalleled accuracy, predictive maintenance, and savings over time.

From identifying disconnected panels to locating potential thermal hot spots, AI drones are setting a new standard for energy infrastructure. Reach out to Nextbrain today to start the future of solar panel inspections with Vision AI.