Within today’s advanced manufacturing ecosystems, artificial intelligence (AI) has revolutionized how production floors operate and optimize time. Even minor inefficiencies — such as extended idle time, machine delays, or untracked processes — can disrupt delivery schedules, reduce resource utilization, and drive up operating costs. As competition intensifies and demand for precision grows, organizations must rely on real-time visibility and intelligent automation to stay ahead.

AI-powered vision systems have emerged as a breakthrough solution, reshaping factory management by offering granular insights into workflows, operator performance, machine health, and production quality. By integrating machine learning, visual analytics, and deep learning capabilities, manufacturers can now eliminate inefficiencies, streamline operations, and achieve higher output consistency. With computer vision for manufacturing productivity, production lines can detect defects instantly, predict failures, automate quality checks, and maintain seamless operational flow across all stages.

Understanding AI Vision Technology in Manufacturing

AI-driven computer vision combines high-resolution imaging with advanced machine learning algorithms that analyze visual data captured from production environments. Unlike traditional sensors that provide limited readings, AI vision systems interpret complex visual patterns, detect abnormalities, identify defects, classify objects, monitor machine conditions, and evaluate worker activities — all without human intervention.

This intelligent visual interpretation empowers factories to run efficiently while maintaining high-quality standards. Studies show that manufacturers lose nearly 20% of productivity due to inadequate operational visibility. These recurring inefficiencies eventually lead to missed targets, reduced reliability, and higher costs. AI vision bridges this gap by offering real-time insights into every step of the production cycle, flagging delays, and enabling quick corrective action.

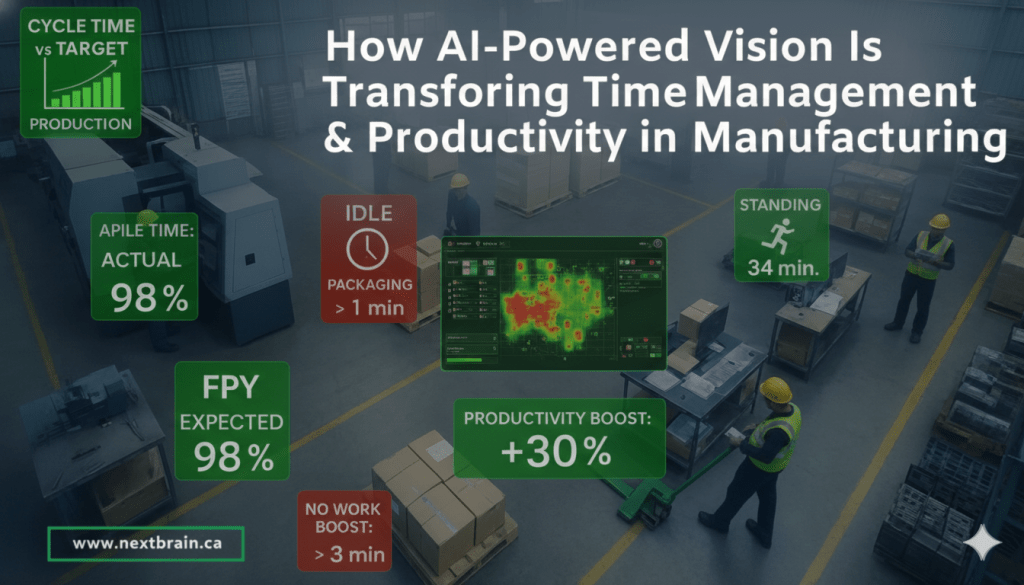

Key Statistics Highlighting AI’s Manufacturing Impact

The global manufacturing sector has witnessed significant improvements after adopting AI-based vision systems. Some notable results include:

Consistent Output & Quality

Manufacturers using AI vision report reduced cycle-time deviations and improved on-time delivery consistency.

Cycle Time Optimization

AI-driven process intelligence enables factories to experience up to 20% higher throughput and as much as 15% improved efficiency.

Real-Time Productivity Tracking

Organizations monitoring tasks and activities through AI-powered systems save up to 25% in labor costs due to optimized workflows and reduced idle time.

Enhanced Workplace Performance

Over 55% of companies using workplace monitoring tools have witnessed nearly 80% improvement in overall productivity.

These metrics prove that AI does more than automate tasks — it transforms operations with measurable improvements in efficiency, accuracy, and output.

Enhancing Time Management With Real-Time AI Insights

The most significant advantage of AI vision systems is their ability to strengthen time-sensitive operations. By continuously analyzing production data, the system detects inefficiencies, delays, safety violations, and bottlenecks well before they escalate.

1. Live Operational Monitoring

AI vision tracks machine speed, operator activity, workstation processes, and material movement in real time. Any deviation — whether a slowdown, extended idle time, or workflow misalignment — is instantly flagged. This leads to faster decision-making, minimized downtime, and smoother operations.

2. Instant Alerts for Quick Response

The moment an anomaly is detected, the system triggers alerts to supervisors. Whether it’s a stalled machine, improper workflow, or operator delay, early intervention prevents disruptions and improves overall performance.

3. Predictive Maintenance Using AI

AI-powered cameras identify early signs of wear, misalignment, leakage, vibration, or overheating. This predictive capability helps manufacturers schedule maintenance before breakdowns occur — significantly reducing unplanned downtime and extending equipment lifespan.

4. Smarter Data-Driven Decisions

AI dashboards offer comprehensive insights into production trends, operator efficiency, resource utilization, and bottleneck points. Leaders can make informed decisions based on real-time analytics rather than assumptions.

5. Automated Quality Assurance

Manual inspection is time-consuming and error-prone. AI vision systems automatically detect defects, deviations, or inconsistencies at high speed and with greater accuracy. This ensures product quality, reduces rework, and enhances customer satisfaction.

Boosting Productivity Through Intelligent Automation

When AI, deep learning, and visual intelligence work together, manufacturing facilities evolve into highly efficient, automated ecosystems. These systems continuously learn from data and improve their decision-making accuracy, contributing directly to productivity gains.

Predictive Maintenance

Visual monitoring allows AI to detect subtle irregularities that human eyes may miss. This prevents machine failures, enabling smoother and uninterrupted operations.

Automated Quality Inspections

AI vision ensures 100% inspection of products and components without slowing down production lines. Real-time defect detection significantly reduces wastage and improves accuracy.

Process Optimization & Workflow Intelligence

AI traceability tools capture operator movements, material handling, and machine cycles to identify inefficiencies. This helps factories optimize labor allocation, improve throughput, and refine workflow distribution.

Inventory & Asset Tracking

AI-powered cameras monitor inventory levels, track asset movement, and automate stock management. This reduces human errors and ensures that production never stops due to material shortages.

Workplace Safety Monitoring

AI-enabled systems detect safety violations — such as PPE non-compliance, unauthorized zone entry, improper machine usage, or unsafe behavior. Preventing accidents not only protects workers but also ensures uninterrupted productivity.

Enhanced Human–Machine Collaboration

By automating repetitive monitoring tasks, AI allows workers to focus on skilled activities. This strengthens human–machine synergy, improves morale, and increases output quality.

Nextbrain: Your Trusted AI Vision Partner for Smart Manufacturing

Nextbrain empowers manufacturing companies to unlock the full potential of AI through advanced computer vision, machine learning, and AI video analytics software. With a deep understanding of industrial challenges, Nextbrain builds scalable, intelligent, and customizable AI solutions that optimize operations, reduce downtime, and deliver measurable results.

Why Manufacturers Choose Nextbrain

1. Tailored AI Strategies

Nextbrain designs custom AI models specifically aligned with each factory’s operational requirements and challenges.

2. Proven Expertise

With extensive experience across AI, ML, and computer vision, Nextbrain delivers robust, high-performance solutions for real-world manufacturing problems.

3. Data-Driven Results

Their AI vision platforms consistently enhance productivity, safety, and efficiency — ensuring strong ROI.

4. End-to-End Support

From strategy and development to deployment and optimization, Nextbrain manages the entire AI transformation journey.

5. Seamless Integration

Their team collaborates closely with production units to ensure smooth implementation, minimal disruption, and sustainable long-term success.

Final Thoughts

AI-powered vision technology is rapidly becoming the backbone of modern manufacturing. By detecting inefficiencies early, automating quality inspections, predicting maintenance needs, and optimizing workflows, AI helps factories unlock unmatched levels of performance and productivity. As the global manufacturing landscape embraces digital transformation, AI vision stands at the forefront of industrial innovation.

If you’re ready to enhance operational efficiency, eliminate downtime, and build a smart manufacturing ecosystem, Contact Nextbrain today and begin your journey toward intelligent automation.

FAQs

1. What is computer vision AI in manufacturing?

Computer vision AI uses cameras and machine learning models to analyze visual data from production lines, enabling defect detection, process tracking, and real-time insights.

2. How does AI improve time management in manufacturing?

AI optimizes time by offering real-time monitoring, predictive analytics, instant alerts, and workflow automation — significantly reducing downtime and delays.

3. What are the main benefits of AI-powered vision systems?

They enhance quality control, automate inspections, predict machine failures, improve safety, and reduce operational inefficiencies.

4. How does Nextbrain help manufacturers adopt AI vision solutions?

Nextbrain provides end-to-end AI vision services including model development, deployment, integration, and ongoing optimization.

5. Does computer vision AI boost workplace productivity?

Absolutely. It reduces errors, improves process visibility, automates repetitive tasks, and enhances machine performance — leading to higher productivity.